TRAXCO is an official

Deemex®

Dealer.

|

Introduction

ELKAT SA has strived to improve existing

technologies and develop new products against

abrasion. DEEMEX Plates is a range of products

that meets the requirements of total wear

solutions, based in the creation of high density

Chromium Carbide Matrix.

It is worldwide known that Chromium Carbides in

the matrix are responsible for wear resistance

and hardness in the other side has a minimal

effect on reducing abrasion loss.

|

Advantages

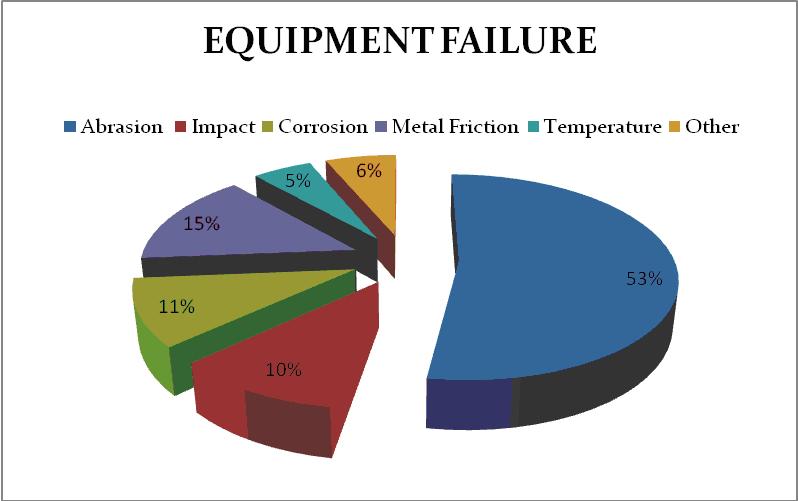

In industry there is always a combination of

wear mechanisms that makes all kind of equipment

to fail. Have you ever consider the real damage

in single mechanism proportions?

DEEMEX products

guaranties high profitability in ore mines,

power plants, refineries, cement industries and

similar industrial applications, because are:

·

Most cost effective way to

combat abrasive wear, due to uniform deposition

of Carbide Matrix in all hard facing thickness.

·

Easy applicable to large scale

projects.

·

Minimizing maintenance and

repairs.

·

Adjust shorter maintenance times

(repair kits).

·

Profiling to any size and shape

(special applications).

·

Wide range of custom overlays.

·

Engineering support through

process and maintenance.

·

Installation of new or semi

finished parts by specialized stuff.

The use of Hard

Facing Technology is worldwide known, especially

in USA and Western European Countries.

|

Products

Our engineers have 40

years of experience in construction, so they developed

the best solution in wear problems. DEEMEX Plates are

reducing maintenance and operating cost providing longer

service life. The production line is suited in Greece

(EU), we assure quality by analyzing the microstructure

and chemical composition in every batch. All the

production is fully automated and all raw materials are

checked for purity and test certificates. The finished

product is checked for composition, carbide content,

tolerances, crack dimension and straightness from fully

equipped testing lab.

We deliver DEEMEX Plates

with all certificates DIN 50049-2.2 for coating and EN

10204:2004-3.1 for base plates, according to EN ISO

9001:2008.

The newest production line

of DEEMEX Plates employs PLC controlled systems ensuring

uniform coating bead width and various welding shape

imprints.

DEEMEX Plates outlast

in high abrasion applications quench and tempered steels

by up to 9 times and up to 42 times mild steel according

to ASTM G65 -00 standard testing.

|

DEEMEX SERIES |

WEAR

PLATES |

C.

(%) |

Cr.

(%) |

OTHER

ELEMENTS |

HARDNESS

ROCKWELL |

|

PLATE

THICKNESS |

|

PLATE |

COATING |

|

|

DMX 100 |

2.7-4.3 |

17-29 |

Mn, B,

Mo, Fe |

50-56 |

≥

4mm |

≥

3mm

≤

10mm |

|

DMX 105 |

4.1-5.1 |

30-32 |

Mn, B,

Mo, Fe |

56-60 |

≥

4mm |

≥

3mm

≤

10mm |

|

DMX 110 |

4.9-5.5 |

32-35 |

Mn, B,

Mo, Fe |

60-64 |

≥

4mm |

≥

3mm

≤

10mm |

|

The Wear Plate

Series (DMX100, 105, 110) come with Standard

Base Material. |

|

STANDARD DEEMEX PLATES |

|

STANDARD BASE

SHEET DIMENSIONS |

STANDARD BASE

MATERIAL |

OPTIONAL BASE

MATERIALS |

900 X 900mm

1150 X 2400mm

1400 X 2900mm |

S 265JR |

Wear Resistant

Steels

Stainless Steels

P 265 GH

З 275 ПР |

|

Customers

After many years of economic losses due

to abrasion, highly industrialized countries

embrace Hard Facing Technology. This is because

hard facing technology reduces maintenance

costs, minimizes the number of repairs, reduces

downtime and generally makes the life of

engineers easier.

DEEMEX technology reduces also investment costs

because carbon steel (S235JR) is used as base

material even under high abrasive conditions.

The industries that mainly effected from this

technological achievement are:

|

Typical

Applications

|

DEEMEX SERIES |

|

WEAR PLATES |

HARDNESS ROCKWELL |

APPLICATIONS |

|

DMX 100 |

50-54 |

Crusher parts, bucket lips, conveyor

screws |

|

DMX 105 |

56-60 |

Chutes, Feeders and Scrolls,

Mixer

blades and components, Rotor blades for

fans in cement industries, wearing parts

for Dedusting systems, Pipes, Scrapers,

Mills |

|

DMX 110 |

60-64 |

Dredge Pump parts, Hoppers, Crusher

Rolls, Screw Conveyors, Blast furnace,

Sinter plant, Cement kilns, Exhaust fan

blades, Pearlite crushers, Mixing tools,

Bunker cladding, Excavator shovels,

Shovel bucket teeth |

|

The Wear Plates (DMX100, 105,

110) come with Standard Base Material. |

DEEMEX

Plates can be (cold, hot) formed at customer

will. |

|

|

|

|